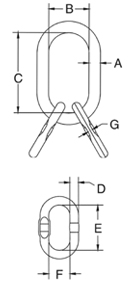

| Size | A-345 Stock No |

Weight Each (lbs.) |

Working Load Limit Based on 5:1 Design Factor (lbs.) |

Proof Load (lbs.)** |

Dimensions (in.) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (in.) | (mm) | A | B | C | D | E | F | G | Deformation Indicator |

||||

| 3/4W | 19W | 1014739 | 3.5 | 12300 | 28400 | .73 | 3.20 | 6.00 | .56 | 3.35 | 1.77 | .30 | 4.00 |

| 7/8W | 22W | 1014742 | 4.8 | 15200 | 35200 | .88 | 3.75 | 6.38 | .56 | 3.35 | 1.77 | .30 | 4.50 |

| 1W | 26W | 1014766 | 9.3 | 26000 | 60000 | 1.10 | 4.30 | 7.50 | .75 | 3.94 | 2.36 | .33 | 5.50 |

| 1-1/4W | 32W | 1014779 | 15.8 | 39100 | 90400 | 1.33 | 5.50 | 9.50 | 1.00 | 6.30 | 3.54 | .51 | 7.00 |

| 1-1/2W | 38W | 1014807 | 34.1 | 61100 | 141200 | 1.61 | 5.90 | 10.50 | 1.25 | 7.09 | 3.94 | .65 | 7.50 |

| 1-3/4 | 44 | 1014814 | 46.7 | 84900 | 169800 | 1.75 | 6.00 | 12.00 | 1.38 | 8.00 | 5.00 | .73 | 7.50 |

| 2 | 51 | 1014832 | 67.2 | 102600 | 205200 | 2.00 | 7.00 | 14.00 | 1.50 | 9.00 | 5.75 | – | 9.00 |

| 2-1/2 | 64 | 1014855 | 206 | 160000 | 320000 | 2.50 | 8.38 | 16.00 | 2.50 | 16.00 | 8.38 | – | 11.00 |

| 2-3/4 | 70 | 1014864 | 282 | 216900 | 433800 | 2.75 | 9.88 | 18.00 | 2.75 | 18.00 | 9.88 | – | 12.50 |

| 4 | 102 | 1014999 | 667 | 373000 | 746000 | 4.00 | 12.00 | 24.00 | 3.50 | 24.00 | 12.00 | – | 15.50*** |

* Ultimate Load is 5 times the Working Load Limit. The maximum individual sublink working load limit is 75% of the assembly working load limit except for 2-1/2”and 2-3/4”, which are 100% of assembly working load limit. Applications with wire rope and synthetic sling generally require a design factor of 5.

** Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9. *** Sublink only. For use with chain slings, contact Atlantic Cordage for proper master link selection