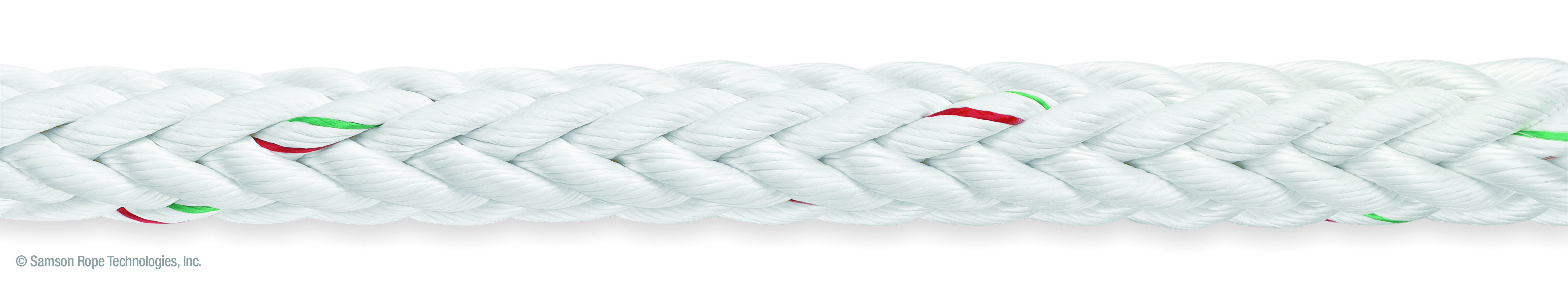

HTP-12 is a 12-strand construction that provides optimum performance in static bending situations by allowing even distribution of loads across the bend, making HTP-12 ideal for use where small D/d ratios are common. Made with high- tenacity polyester fiber to provide good flex-fatigue resistance and shock absorption, HTP-12 is available with Samson’s proprietary Pro-Gard marine finish for enhanced performance.

Applications

- General Working Line

- Mooring Tails

Features and Benefits

- Easy to inspect

- Flex-fatigue resistant

- Pro-Gard Marine Finish

- Easy to splice

- Mitigates shock

Specifications

FIBER: Polyester

SPECIFIC GRAVITY: 1.38

SPLICE/CLASS: Round Plait Class I

ELASTIC ELONGATION PERCENTAGE:

At % of break strength

10%…………..1.70%

20%…………..3.40%

30%…………..5.80%

COLOR: White with green and red ID

| DIAM. (inch) | CIRC. (inch) | WEIGHT PER 100 FT. (lbs) | AVG. STRENGTH (lbs) | MIN. STRENGTH (lbs) | DIAM. (mm) | CIRC. (mm) | WEIGHT PER 100 M (kg) | AVG. STRENGTH (kg) | MIN. STRENGTH (kg) | ISO 2307 STRENGTH (metric tons) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2″ | 4 1/2″ | 72.0 | 91,800 | 82,600 | 36 | 108 | 107 | 41,600 | 37,500 | 41.6 |

| 1 5/8″ | 5″ | 93.0 | 113,000 | 102,000 | 40 | 120 | 138 | 51,300 | 46,100 | 51.3 |

| 1 3/4″ | 5 1/2″ | 111 | 137,000 | 123,000 | 44 | 132 | 165 | 62,100 | 55,900 | 62.1 |

| 1 7/8″ | 5 5/8″ | 118 | 145,000 | 131,000 | 46 | 136 | 176 | 65,800 | 59,200 | 65.8 |

| 1 15/16″ | 5 13/16″ | 136 | 157,000 | 141,000 | 47 | 141 | 202 | 71,200 | 64,100 | 71.2 |

| 2″ | 6″ | 146 | 168,000 | 151,000 | 48 | 144 | 217 | 76,200 | 68,600 | 76.2 |

| 2 1/8″ | 6 1/2″ | 159 | 185,000 | 167,000 | 52 | 156 | 237 | 83,900 | 75,500 | 83.9 |

| 2 1/4″ | 7″ | 195 | 210,000 | 189,000 | 56 | 168 | 290 | 95,300 | 85,700 | 95.3 |

| 2 3/8″ | 7 1/8″ | 213 | 231,000 | 208,000 | 57 | 174 | 317 | 105,000 | 94,300 | 105 |

| 2 1/2″ | 7 1/2″ | 231 | 242,000 | 218,000 | 60 | 180 | 344 | 110,000 | 98,800 | 110 |

| 2 5/8″ | 8″ | 258 | 267,000 | 240,000 | 64 | 192 | 384 | 121,000 | 109,000 | 121 |

| 2 3/4″ | 8 1/2″ | 285 | 296,000 | 266,000 | 68 | 204 | 424 | 134,000 | 121,000 | 134 |

| 2 7/8″ | 8 5/8″ | 312 | 317,000 | 285,000 | 70 | 208 | 464 | 144,000 | 129,000 | 144 |

| 3″ | 9″ | 330 | 332,000 | 299,000 | 72 | 216 | 491 | 151,000 | 136,000 | 151 |

| 3 1/8″ | 9 1/2″ | 366 | 361,000 | 325,000 | 76 | 228 | 545 | 164,000 | 147,000 | 164 |

| 3 3/16″ | 9 9/16″ | 411 | 397,000 | 357,000 | 78 | 232 | 612 | 180,000 | 162,000 | 180 |

| 3 7/16″ | 10 5/16″ | 447 | 430,000 | 387,000 | 84 | 252 | 665 | 195,000 | 176,000 | 195 |

| 3 5/8″ | 11″ | 540 | 477,000 | 429,000 | 88 | 264 | 804 | 216,000 | 195,000 | 216 |

ISO strength specifications are for unspliced rope. All other strength specifications are for spliced rope.