- Forged from special bar quality carbon steel, suitable for cold forming.

- Swage Socket terminations have an efficiency rating of 100% based on the catalog strength of wire rope.

- Hardness controlled by spheroidize annealing.

- Stamp for identification after swaging without concern for fractures (as per directions in National Swaging Brochure).

- Swage sockets incorporate a reduced machined area of the shank which is equivalent to the proper “After Swage” dimension. Before swaging, this provides for an obvious visual difference in the shank diameter. After swaging, a uniform shank diameter is created allowing for a QUIC-CHECK® and permanent visual inspection opportunity.

- Designed to quickly determine whether the socket has been through the swaging operation and assist in field inspections, it does not eliminate the need to perform standard production inspections which include gauging for the proper “After Swage” dimensions or proof loading.

- U.S. Patent 5,152,630 and foreign equivalents.

S-502

NOTE: S-502 Swage Sockets are recommended for use with 6 x 19 or 6 x 36, IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope. Before using any National Swage fitting with any other type lay, construction or grade of wire rope, it is recommended that the termination be destructive tested and documented to prove the adequacy of the assembly to be manufactured. In accordance with ASME B30.9, all slings terminated with swage sockets shall be proof loaded.*

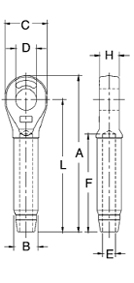

| S-501 and S-501B Open Socket Specifications | Max. After Swage Dim. (in.) |

Press / Die Data | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-501 Stock No. | S-501B Stock No. ** | Rope Size* | Wt. Each (lbs.) | Before Swage Dimensions (in.) |

Die Description |

Stock No. | Side Load | |||||||||||||

| (in.) | (mm) | A | B | C | D | E | F | H | L | M | N | 500 1000 1500 Ton 5 x 7 |

1500 3000 Ton 6 x 12 |

1500 Ton 6 x 12 |

3000 Ton 6 x 12 |

|||||

| 1039021 | 1054001 | 1/4 | 6 | .52 | 4.78 | .50 | 1.38 | .69 | .27 | 2.19 | .69 | 4.00 | .38 | 1.47 | .46 | 1/4 Socket | 1192845 | – | – | – |

| 1039049 | 1054010 | 5/16 | 8 | 1.12 | 6.30 | .78 | 1.62 | .81 | .34 | 3.25 | .80 | 5.34 | .48 | 1.67 | .71 | 5/16-3/8 Socket | 1192863 | – | – | – |

| 1039067 | 1054029 | 3/8 | 9-10 | 1.30 | 6.30 | .78 | 1.62 |

.81 |

.41 | 3.25 | .80 | 5.34 | .48 | 1.67 | .71 | 5/16-3/8 Socket | 1192863 | – | – | – |

| 1039085 | 1054038 | 7/16 | 11-12 | 2.08 | 7.82 | 1.01 | 2.00 | 1.00 | .49 | 4.31 | 1.00 | 6.69 | .56 | 1.96 | .91 | 7/16-1/2 Socket | 1192881 | – | – | – |

| 1039101 | 1054047 | 1/2 | 13 | 2.08 | 7.82 | 1.01 | 2.00 | 1.00 | .55 | 4.31 | 1.00 | 6.69 | .56 | 1.96 | .91 | 7/16-1/2 Socket | 1192881 | – | – | – |

| 1039129 | 1054056 | 9/16 | 14 | 4.67 | 9.54 | 1.27 | 2.38 | 1.19 | .61 | 5.38 | 1.25 | 8.13 | .68 | 2.21 | 1.16 | 9/16-5/8 Socket | 1192907 | – | – | – |

| 1039147 | 1054065 | 5/8 | 16 | 4.51 | 9.54 | 1.27 | 2.38 | 1.19 | .68 | 5.38 | 1.25 | 8.13 | .68 | 2.21 | 1.16 | 9/16-5/8 Socket | 1192907 | – | – | – |

| 1039165 | 1054074 | 3/4 | 18-20 | 7.97 | 11.61 | 1.56 | 2.75 | 1.38 | .80 | 6.44 | 1.50 | 10.00 | .78 | 2.69 | 1.42 | 3/4 Socket | 1192925 | – | – | – |

| 1039183 | 1054083 | 7/8 | 22 | 11.52 | 13.37 | 1.72 | 3.13 | 1.63 | .94 | 7.50 | 1.75 | 11.63 | .94 | 3.20 | 1.55 | 7/8 Socket | 1192943 | – | – | – |

| 1039209 | 1054092 | 1 | 24-26 | 17.80 | 15.47 | 2.00 | 3.69 | 2.00 | 1.07 | 8.63 | 2.00 | 13.38 | 1.07 | 3.68 | 1.80 | 1 Socket | 1192961 | – | – | – |

| 1039227 | 1054104 | 1-1/8 | 28 | 25.25 | 17.35 | 2.25 | 4.06 | 2.25 | 1.19 | 9.75 | 2.25 | 15.00 | 1.19 | 4.18 | 2.05 | 1-1/8 Socket | 1192989 | – | – | – |

| 1039245 | 1054113 | 1-1/4 | 32 | 35.56 | 19.20 | 2.53 | 4.50 | 2.50 | 1.34 | 10.81 | 2.50 | 16.50 | 1.27 | 4.64 | 2.30 | 1-1/4 Socket | 1193005 | – | – | – |

| 1039263 | 1054122 | 1-3/8 | 34-36 | 43.75 | 21.10 | 2.81 | 5.25 | 2.50 | 1.46 | 11.88 | 2.41 | 18.13 | 1.46 | 5.25 | 2.56 | 1-3/8 Socket | 1193023 | – | – | – |

| 1039281 | 1054131 | 1-1/2 | 38-40 | 58.50 | 23.17 | 3.08 | 5.50 | 2.75 | 1.59 | 12.81 | 3.00 | 19.75 | 1.65 | 5.70 | 2.81 | 1-1/2 Socket | 1193041 | 1191267 | 1195355 | 1195192 |

| 1039307 | 1054140 | 1-3/4 | 44 | 88.75 | 26.70 | 3.40 | 6.25 | 3.50 | 1.87 | 15.06 | 3.50 | 23.00 | 2.07 | 6.67 | 3.06 | 1-3/4 Socket | 1193069 | 1191276 | 1195367 | 1195209 |

| 1042767 | 1054159 | 2 | 48-52 | 146.2 | 31.15 | 3.94 | 7.80 | 3.75 | 2.12 | 17.06 | 4.00 | 26.75 | 1.81 | 8.19 | 3.56 | 2 Socket | 1193087 | 1191294 | 1195379 | 1195218 |

* Maximum Proof Load shall not exceed 50% of XXIP rope catalog breaking strength.